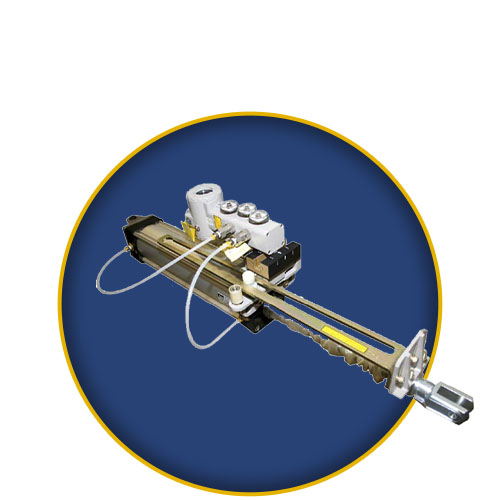

ACP303

PROFIBUS PA Pneumatic Cylinder Actuator

The ACP303 combines the strength of pneumatic cylinders with the potentialities of the FY intelligent micro-processed positioner, which allows for modulated control applications. The ACP modular structure allows for its being mounted on a wide variety of cylinder sizes, by using a single version of mounting support. The Pneumatic Cylinder Actuator (ACP303) is available in several sizes according to the required function and travel. There are two types of models: linear or rotary, for different operation travel.

Through the action of the FY301 positioner, the position of the pneumatic double action cylinder is controlled with the use of the linear or rotary magnet system via-Hall effect. This positioning system, overcomes one the biggest disadvantages of the pneumatic action, namely, obtaining intermediary cylinder stops. More than simply taking the micro-processing to the cylinder, the ACP303 is presented in its linear and rotary versions, which gives the user freedom of application on several final control elements, such as dampers (for oven batch control), water dams, large valves and other applications that require control of movement.

The ACP303 receives a signal on the PROFIBUS PA standard protocol emitted by the controller who activates and directs the cylinder to its exact position, as required, and compliant to the strategy and tuning of the control loop on which it is applied. By including intelligence in the cylinder, the ACP303 allows for the user to configure the feature of opening the cylinder with the control signal received.

Furthermore, the easy use of the PROFIBUS communication protocol in a few minutes provides a simple interface between the field and the control room, and multiple features that reduce installation, operation and maintenance costs:

- Compact and modular project;

- Easy to install;

- Non-contact position measurement via Hall Effect sensor;

- Simple parameter configuration through local controls and indicators;

- Weather proof, explosion proof, intrinsically safe;

- Change of valve opening characteristic via software;

- Auto-configuration in a few minutes;

- Auto-lubrication with no need for external lubricants;

- Optional limits switches;

- Filter regulator incorporated.

FY Some features:

|

Input and Communication Protocol |

PROFIBUS, only digital, compliant with IEC 61158-3 (H1) 31,25 Kbit/s with powered by bus. |

|

Output |

Output for 0 to 100% actuator of the supplied pressure air power. Simple or double action. |

|

Power Supply |

Bus power: 9 - 32 Vdc. |

|

Configuration |

Basis configuration can be done through local adjustment with magnetic tool only if the equipment has a display. |

|

Pressure Supply |

1.4 - 7 bar (20 -100 psi). Free of oil, dust and water, compliant with ANSI/ISA S7.0.01-1996. |

|

Position Sensor |

Non-contact Hall effect sensor. |

|

Display LCD |

Rotative LCD, with 4 ½ - numerical digit and 5-character alphanumerical. Function and status icons. |

|

Material of Construction |

Injected low copper aluminum with polyester painting or 316 Stainless Steel housing, with Buna N O-Rings on cover. |

|

Temperature Limits |

Operation: -40 to 85ºC (-40 to 185 ºF). |

|

Humidity Limit |

0 to 100% RH (Relative Humidity non-considerable). |