Truly open systems & Asset Management: Strategic Tools for competitive companies

|

|

Introduction

Does your plant use a truly open system? Does you plant rely on luck to deal with downtime? Undoubtedly your company runs the risk not to be competitive.

In present times, the industrial automation world counts only with two ways for a company to become competitive: the optimization of processes using truly open systems and asset management.

Optimization ensures performance improvement, reduction of raw material costs, better quality etc.

The more information you get, the better the plant is operated: more products can be generated and more profits obtained. Digital information and truly open systems allow gathering information on a plant´s most different types and targets, as no one has ever imagined. In this sense, the Fieldbus technology (Foundation Fieldbus, PROFIBUS, HART, DeviceNet, AS-i, etc) can turn valuable bits and bytes into a profitable relationship and also get a qualitative gain for the entire system.

This will only be possible if the process runs smoothly, as a direct consequence of asset management and good practices to reduce downtime, increase plant availability and cutting down maintenance costs.

Truly Open Systems

Nowadays many suppliers of systems state that their control systems are open, but it is not true in practice. These systems are only supplementary to digital technology, being in fact proprietary. A system cannot be considered an open one just for having a digital fieldbus bus.

A truly open system makes your horizons much wider. It means: possibility of diagnostics, more tolerance to failures, instantiable function blocks, FFBs (Flexible Blocks), connectivity with the Fieldbus technology, HSE (Hight Speed Internet) connectivity, OPC connectivity and many more features that provide complete control and not only a mere bus with proprietary integrations. When purchasing a control system be aware that it agregates information that benefit decision making and ensure operation excellence.

A truly open system perfectly integrate several open technologies software to the hardware, while being compatible with third-party software and hardware (bear in mind that communication drivers and dedicated files belong to the past). The user must feel free to chose the components and even build his own system. Old proprietary technologies still exist, but they may not be available when your company needs to undergo an expansion.

The flexibility and the capability for expanding the architecture of a truly open system make possible to get re-configurations and expansions that meet the new process conditions without large re-investments. Before deciding which technology to use in your new projects, make sure that in the future it will be possible to expand or even make modifications without the need for new investments beyond your budget. Modern technologies enable fast response to changes in the market conditions. You may need to increase your production capacity, launch a new product, or meet another requirement.

Invest in a truly open system is to ensure operational excellence for the coming 20 years or more.

For more details on a truly open system, access https://www.smar.com.br/en/system302. SMAR SYSTEM302 was developed specially to meet these new challenges.

Management and Maintenance System

A management and maintenance system must have resources that make possible for the user to identify or predict in an easy and quick way any malfunction in your plant. It must be able to easily generate statistical data, history, reports and provide easy access from anywhere, even outside the plant. Furthermore, it should benefit from the resources of modern software network and architecture, like OPC interface, Microsoft DNA and via-WEB access, whose tools offer the user wide plant visibility, anytime, any place, or anywhere else, through the PC, PDA or cell phone (WAP, SMS). Today it is common to find tools in the market using the very WEB browser as platform for graphic interfaces with the user. An example is the AssetView by SMAR, an integral SYSTEM302 part.

As a native resource on the majority of the most used operational systems (Windows, Linux, Solaris, QNX etc), the WEB Browsers simplify the training and maintenance of the actual system, while eliminating the need for the traditional user update. An important aspect is that, besides having in its database common failure situations, it must have learning purpose conditions, since it includes specific solutions for similar cases and saving time on future repairs.

It is fundamental that the system uses open technologies to ensure interoperability. SMAR AssetView was developed with this philosophy and today makes the user´s life easier, by guaranteeing competitive edge to companies.

Figure 1 - AssetView

Benefits from the Asset Management

The Fieldbus technology (Foundation Fieldbus, PROFIBUS, HART) enables abundant information, not only pertinent to the process, but especially from the field equipment. Thus, diagnostics conditions may save operational and maintenance costs, mainly in hazardous areas or those hard to reach. Notice that most jobs on the field do not really mean that an equipment has some problem. On the other hand, an effective management ensures going out on the field for some real problem and this is easily located. The management of the field information makes it possible to select data that meet the targeted production, maintenance and quality needs: the information is directed to the right persons and areas, while improving the processes.

Notice that the great advantage is the easy access to the information with reliability, as the data belong to the same data base, regardless from the company hierarchy; everybody speaks the same language, avoiding misunderstandings. Furthermore, the easy access guarantees fast and effective responses that enable strategies for problem solving, with minimum downtime. Next, follow some features enabled by asset management.

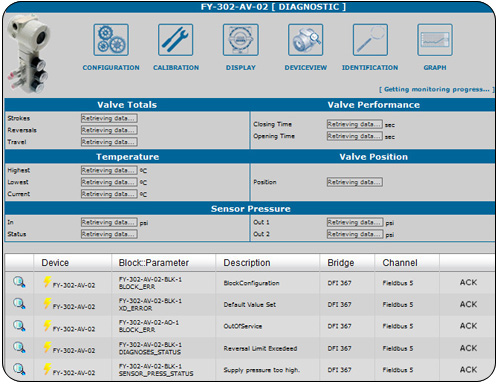

For example, on the AssetView screen on figure 2, the user can easily see the general diagnostics picture of his plant and identify the equipments operating outside their normal conditions. Any given situation, even the lack of communication, is registered and it enables tracking the data base, and easily obtain a life history of the equipment.

Figura 2 - List of diagnostics events

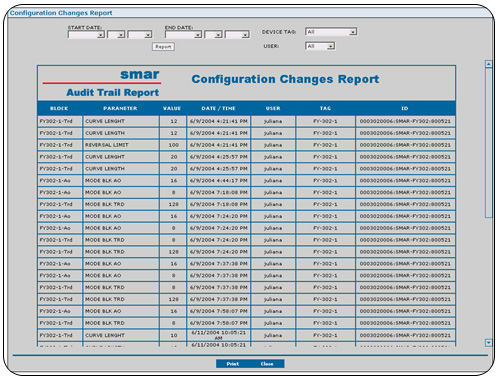

Figure 3 shows the conditions for the generation of reports pertinent to changes in the configuration.

These reports are based on changes of configuration and calibration and provide easy reconciliation of the configurations.

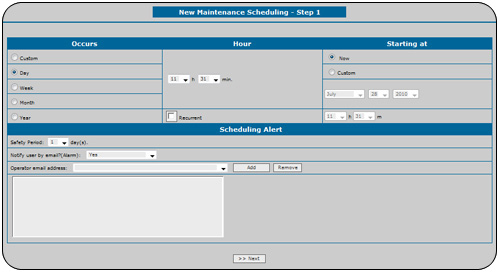

It simplifies the schedule of maintenance for the equipments and the information is anticipated by email to the maintenance team and personnel involved. See figure 4.

Figure 3 – Report on configuration changes

Figure 4 - Maintenance Schedule

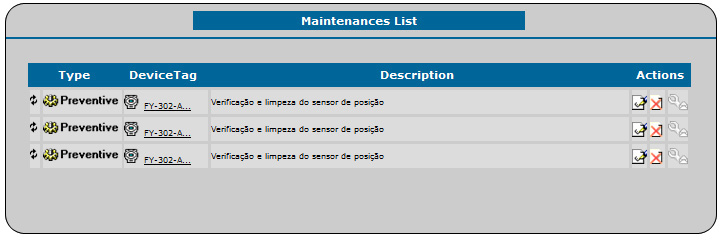

Figure 5 shows the list of the scheduled maintenances.

Figure 5 - List of scheduled maintenances

As companies today want information that facilitates decision making, below are advantages and benefits of asset management, an Internet tool that requires little training:

- Easy access to the information all over the facilities, from plant floor to management level;

- Information uniformity and reliability on the several hierarchy ranks. Plentiful data for easy decision making;

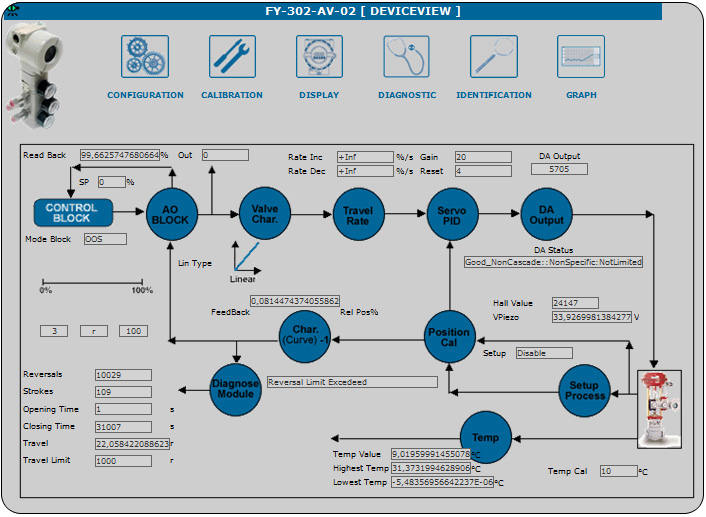

- Infrastructure and technology for on-line monitoring (see fig. 6), and to configure, calibrate and manage field equipment for the best results in terms of performance and costs reduction;

- The best maintenance (mainly proactive) proactive practices through diagnostics management and maintenance schedule;

- Audit Trial;

- Minimize the spare parts inventory;

- Increase the availability and the plant´s operational security and reduce downtime;

- Preventive Maintenance reduces the time lost with the maintenance of equipments that actually don´t need it.;

- Guaranteed operational gains and costs reduction that favor the decrease of general costs.

Figure 6 - Device View Screen

Preventive diagnostics.This is what you valve needs.

Figure 7 - Preventive Diagnostics

More information about AssetView tool.

Conclusion

Undoubtedly, Truly Open System and Asset Management are important tools for a company´s strategic management. They create and give operational reliability, and adjust the production, maintenance and management areas in order to meet common goals: increase productivity, improve quality and reduce costs, mandatory on any business segment. In addition, they represent the best option in terms of return of investments.

.jpg)