Wireless - ISA 100

Introduction

The need for automation in industry and in various segments is associated, among several aspects, with the possibilities for increasing the speed of information processing, since operations are becoming complex and variable, requiring a large number of controls and regulatory mechanisms to enable more agile decision and therefore increase levels of productivity and efficiency of the production process within the premises of operational excellence.

Remember that the use of communication protocols in industrial automation has a high requirement for reliability and robustness.

The solution should provide a methodology for industry management in a transparent way and ensure that all efforts are directed to achieve the goal, facilitating decision-making when there are changes to the relevant performance indicators or a deviation related to the planning.

Users and customers must be carefulwhen choosing and defining an automation system and control, where in this definition must take into consideration several criteria and can be in timing with the technological advancement.

The more information you get, better a plant can be operated: more products can be generated and more profits obtained. Digital information and truly open systems allow gathering information on a plant´s most different types and targets, as no one has ever imagined. In this sense, the Fieldbus technology (Foundation Fieldbus, PROFIBUS, HART (WirelessHART™), DeviceNet, AS-i, etc) can transform valuable bits and bytes into a profitable relationship and also get a qualitative gain for the entire system. It is not enough just to think in fieldbus, you should be aware of the general benefits that an automation and control system can provide.

The industrial communication revolution in the technology plays a vital role in the optimization of the process systems and has made a valuable contribution toward improving the use of resources.

The information technology played a decisive role in the development of the automation technology and changed the hierarchies and structures of offices. It now arrives to the industrial environment and its several areas, from process and manufacture industries to buildings and logistic systems. The possibility of communication between devices and the use of standardized, open and transparent mechanisms are essential components of today’s automation concept.The communication expands rapidly in the horizontal direction at the field level, as well as in the vertical direction integrating all of the hierarchy levels of a system. According to the characteristics of the application and the maximum cost to be achieved, a gradual combination of different communication systems offers the ideal conditions for open networks in industrial processes.

In previous articles we have seen some details of WirelessHART™. In this article, we will discuss shortly of the ISA SP100 standard.

Wireless Networks and the market

Today we see in the market various proprietary networks and also some standardized networks.There are many protocols related to the upper layers of technology (ZigBee, WirelessHART™, ISA SP100) and IEEE 802.15.4 (2006) protocol for the lower layers. The IEEE 802.15.4 protocol defines the characteristics of physical layer and medium access control for the LR-WPAN (Low-Rate Wireless Personal Area Network).

.jpg)

Figure 1 - IEEE 802.15.4 2012 Market Share Projection

The standardization for wireless networks shows that, although there are some differences, the standards are converging to the ISA SP100 and WirelessHART™ and HCF HART Foundation has been adopted today as standard for Foundation Fieldbus and PROFIBUS, respectively. Let's comment a little about the ISA SP100.

The ISA 100 standard

The ISA100 is a standard of industrial network wireless developed by SP100 committee (established in 2005) of the ISA.

This standard is very interesting, it supports the implementation of protocols such as HART, Profibus, CIP (Common Industrial Protocol) and Foundation Fieldbus on top of your application layer. See OSI model in Figure 2.

.jpg)

Figure 2 – ISA 100 and OSI model

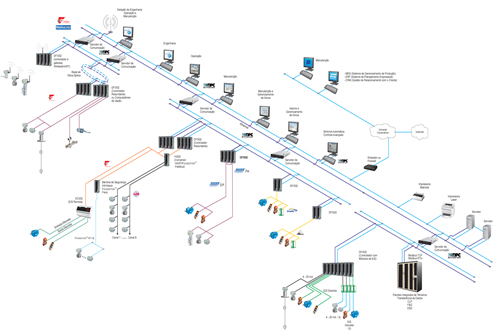

The figure 3 shows an ISA100, it is a basic network and figure 4 shows its stack.

.jpg)

Figure 3 – ISA 100 - Basic Network

Some features of the ISA 100:

- Reliability (enhanced error detection, frequency hopping)

- Predictability (TDMA, Quality of Service levels)

- Security

- Supports for multiple protocols: HART, Profibus, Modbus, FF, etc.

- It is also optimized for long battery life applications and also supports battery powered routers.

- Applications in process control and manufacturing

- Interoperability

- Several manufacturers of ASICs dedicated to the standard

- Star and Mesh Topology

- Designed to meet the most diverse applications classes (see Figure 5)

Etc.

.jpg)

Figure 4 – Stack - SP100

.jpg)

Figure 5 - ISA 100: Standard for different classes of applications

Figure 6 - SYSTEM302, open system based on digital networks.

Conclusion

The technological factor and innovation are responsible for the disruption and/or improvement of the techniques and measurement processes and control.This way we can have gains related to competitiveness.The disruption with conventional technology will be a matter of time and herewithwill expand the possibilities of success with innovation required by the market, in this case, truly open automation systems (see Figure 6, https://www.smar.com.br/en/system302) with digital technologies, network-based industrial, wireless connectivity with several advantages compared to SDCDs conventional.

The change of process control 4-20 mA technology for digital networks and open systemsalready is in a stage of technological maturity andusers are reaping its benefits.This change is viewed as a natural process required by the new needs of quality, reliability and security in the market. Their use have a competitive advantage in the sense that this new technology brings more productivity by reducing process variability and reducing the downtime of the control loops.

Smar Wireless line supports the WirelessHARTTM and also, in the future, the ISA 100 technology.

Please see the next articles about Wireless technology in Smar website.

References:

- Technical Articles - César Cassiolato

- SMAR's Manuals

- https://www.smar.com.br/en/system302

- https://www.smar.com.br/en

- http://tinyos.stanford.edu/ttx/2007/viewgraphs/standards-sp100.pdf

- Internet researches