WirelessHART

|

|

Introduction

The need for automation in the industry and several areas is associated mostly to the possibility of increasing the speed on the information process. The operations are increasingly more complex and varied, needing a great number of controls and regulation mechanisms that allow more agile decision making, while increasing the level of productivity and efficiency of the productive process within the premises of operational excellence.

Automation makes possible to save energy, work force and raw materials, better product quality control, better plant utilization, increased productivity and operational safety. In essence, industrial automation raises the levels of continuity and global control of the process and brings the closest possible the real production figures to the plant nominal capacity, while reducing to a minimum stoppages for corrective maintenance and due to the lack of raw material.

In addition, the arrival of automation systems based on Field networks and digital technology brought many benefits in terms of maintenance and increasing operational availability and safety. Furthermore, automation goes beyond the limits of plant floor and continues through the finished product, to reach wider borders: business automation.

The complete solution must provide a transparent industry management methodology and direct all the efforts towards an established goal, hence facilitating decision making when needing changes relevant to the performance of the indicators or a diversion from the original plan.

Users and clients alike should be attentive when choosing and defining an automation and control system, whose definitions must consider several criteria and match the technological progress.

The more the information, the more a plant can be operated and therefore generate more products and financial results. Digital information and really open systems allow gathering plant data from the most varied types and its goals as never before. All of this may turn valuable bits and bytes into a profitable relationship through the Fieldbus technology (Foundation Fieldbus, Profibus, HART (WirelessHARTTM), DeviceNet, Asi, etc), while improving the quality of the entire system.

The industrial communication revolution on the automation technology is proving its huge potential for the optimization of process systems and has contributed considerably for improving the use of resources. The information technology has been decisive for the development of the automation technology, by altering the hierarchies and structures at the most different industrial sectors, starting on the process and manufacture industries. The capacity of communication between devices and the use of standardized, open and transparent, mechanisms are inseparable components on today´s automation concepts.

Let´s see next, briefly, details on the WirelessHARTTM. network. A series of articles on this technology will detail the protocol, its mechanisms and advantages. Go to: https://www.smar.com.br/en/technical-articles

Wireless Networks

In the last few years, the wireless network technology underwent great technological advancements, which may provide safety, reliability, stability, self-organization (mesh), low consumption, power management systems and long-life batteries.

Among the benefits, enhanced are:

- Reduction of costs and simplified installations

- Reduction of maintenance costs due to the simplicity of the installations

- Monitoring in difficult access or hazardous locations

- Scalability

- Physical integrity of installations with less liability to mechanical and electrical damages (broken cables, bus short circuits, chemical attacks, etc)

In today´s market there are several proprietary or standard networks. Also there are many protocols related to the upper layers of the technology (ZigBee, WirelessHARTTM, ISA SP100) and the IEEE 802.15.4 (2006) protocol for the lower layers. The latter defines the characteristics of physical layer and access control for the LR-WPAN (Low-Rate Wireless Personal Area Network).

The standardization of wireless networks shows that, regardless of their differences, the standards are converging, respectively, to the SP100 and WirelessHARTTM (ISA)and the HCF (HART Foundation, the same as for Foundation Fieldbus and Profibus). Let´s comment a bit the WirelessHARTTM.

WirelessHARTTM

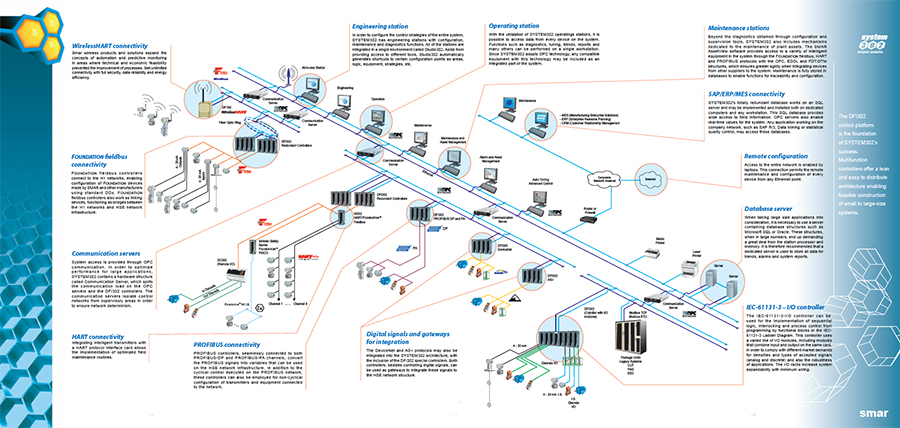

The structure of a WirelessHARTTMnetwork is represented on the figure 1 diagram, whose communication is done through a gateway. Consequently, the gateway must be as functional as a package router for a specific destination (network device, host application or network manager). The gateway uses the HART command standard to communicate with the network device and the host applications.

.jpg)

Figura 1– WirelessHARTTM

The WirelessHARTTM is incorporated in the HART 7, the first open wireless communication standard developed to meet the process industry needs.

It operates on the 2.4 GHz ISM using the Time Division Multiple Access (TDMA) to synchronize the communication between the several network equipment. The entire communication is carried out inside a 10 ms time slot. Time slots make up a superframe.

The WirelessHARTTM supports channel hopping in order to avoid interferences and reduce the effects of multi-path fadings. The HART protocol was created based on the OSI protocol layer 7.

With the incorporation of the wireless technology to the HART, there appeared two new Data Link layers: token-passingand TDMA. Both support the HART application layers.

On figure 2 we have the first WirelessHART HSE (High Speed Ethernet) controller, a SMAR device that again innovates in the market: a controller with open digital technology that integrates with HSE-based systems.

A WirelessHARTTM communication network is structured in loops, where each sensor works as a router or as a repeater. So, the range of a network does not depend only on a central gateway and allows the configuration of a wide distributed network structure. It is an intelligent way to guarantee that the system is resetted and find alternate routes, when an obstruction may interrupt a communication channel, hence increasing and ensuring network availability.

The WirelessHARTTM adopts an architecture that uses a mesh network based on the IEEE 802.15.4 standard, operating on the 2.4 GHz range. Radios use the DSSS method (for Direct-Sequence Spread Spectrum), which provides secure and reliable communication synchronized between the network devices, by utilizing TDMA (Time Division Multiple Access).

The mesh networks allow for network nodes to communicate between them, hence establishing redundant paths to the basis with increased reliability, so that if a path is blocked, new alternate routs for the message to reach its final destination. This type of network also provides scalability, simply by adding more network nodes or repeater. Another feature is that the bigger the network, the better reliability, as new alternate paths will be automatically created.

A WirelessHARTTM network has three main devices:

- Wireless Field devices: Field equipment

- Gateways: allow the communication between field equipment and the control applications

- Network Manager: responsible for network configuration, management of communication between the devices, communication routes and network status management. The Network Manager may be integrated in a gateway, host application or process controller.

.jpg)

Figure 2 – Wireless system with DF100 (WirelessHARTTM controller).

Figura 3 – SYSTEM302, open system based on digital networks.

Conclusion

Technology and the technological innovation are responsible for breaking with or improving the current measuring and control techniques. It may bring gains in terms of competitiveness. Breaking with the conventional technology will be a matter of time. The possibilities of success will grow with the market demand for innovation, namely, truly open automation systems (see figure 3, https://www.smar.com.br/en/system302) with digital technologies based on industrial networks, wireless connectivity and several advantages over conventional SDCDs.

The change of the control of the 4-20mA technology for digital networks and open systems has already reached a stage of technological maturity and users are harvesting the benefits. This move is seen as a natural process prompted by the new requirements for market quality, reliability and safety. Its use brings competitive edge, in the sense that this new technology increases productivity via the reduction of process variability and the unavailability of control loops.

Wait for the coming articles on the WirelessHARTTM.