DT300Series

Density Transmitters - Models and Applications

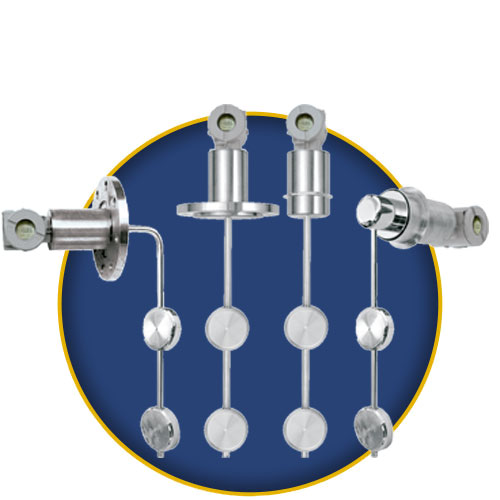

The DT300 Series is available in two models:

- DT300I (Industrial Model) for general purpose;

- DT300S (Sanitary Model) for food and other applications where sanitary connections are required.

Both models have two mounting types: top mounting (straight type) and side mounting (curved type).

Installation may be done either in open or pressurized tanks, or directly in pipes since the DT300 is suitable for dynamic and static fluids.

The Sanitary model that meet 3-A Certification (Authorization N° 1399) uses a Tri-Clamp connection to allow a quick and easy connection and disconnection from the process. The wetted surface finish is polished and then is free of crevices where food or bacteria can be collected. 3A is the most widely accepted sanitary standard in the food, drug and beverage industry.

Applications

- Sugar and Alcohol Processing Plants: Brix of the sugarcane juice, brix of the must, brix of the syrup, brix of the molasses, brix of the solved juice, calcium solution of the Baumé, interface level of the hexane cycle, lime density, INPM degree of the hydrated alcohol, INPM degree of the anhydrid alcohol, etc.

- Dairy Product Industries: Condensed milk, Lactose, Yogurt, Cream cheeses, Lactic Acids, etc.

- Food Industry: Vegetable oils, miscellaneous extractions, fruit syrup, starch dilution, glucose, jams, jellies, sweets, honey, tomato pulp, citrus juices, etc.

- Pulp and Paper Industries: Black liquor, green liquor, white liquor, red liquor, caustic soda concentration, ash dilution, talc dilution, pulp dilution, ink concentration, potassium hydroxide, etc.

- Beverage Industry: Beer (Plato degree in the fermentation process) Soft Drinks (brix of the liquid sugar, etc.), liquors, wines, soluble coffee, malt, tequila, etc.

- Chemical Industry: Acids, concentration/mixture, caustic soda, glycol, salt solution, detergent, toluene, urea, potassium, etc.

- Mining Slurries: Mineral pulp, extraction of thins, flotation, thickening, acid concentration, starch dilution, scrapers, lime mud.

- Petrochemical Industry: Gas washing water, lubricant oils, aromatic extraction, fuel oils, gasoline, kerosene, water/oil interface level.