DT300Series

Density Transmitters - Specifications

Functional Specifications

|

Output and Communication Protocol

|

HART®: Two-wire, 4-20 mA with super-imposed digital communication (HART® Protocol).

Foundation fieldbusTM e PROFIBUS PA: Digital only. Complies with IEC 61158-2:2000 (H1): 31.25 kbit/s voltage mode, bus powered. |

|

Power Supply/Current Consumption

|

HART®: 12-45 Vdc.

Foundation fieldbusTM e PROFIBUS PA: Bus powered: 9 to 32 Vdc. Quiescent current consumption: 12 mA. |

|

Indicator

|

4½-digit numerical and 5-character alphanumerical LCD indicator (optional).

|

|

Hazardous Area Certifications

|

HART®, Foundation fieldbusTM e PROFIBUS PA: Explosion proof, weather proof, intrinsically safe, CEPEL, Dekra/EXAM, FM, NEMKO and NEPSI.

Foundation fieldbusTM e PROFIBUS PA: FISCO Ex ia IIC T4 (CEPEL, Dekra/EXAM, NEPSI) and FNICO Ex nl IIC T4 (CEPEL, Dekra/EXAM) |

|

Other Certification

|

HART®, Foundation fieldbusTM e PROFIBUS PA:3A Sanitary Standard.

|

|

Zero and Span Adjustments

|

Noninteractive, via digital communication or local adjustment.

|

|

Failure Alarm (Diagnostics)

|

Detailed diagnostics through communication for all protocols.

HART®:In case of sensor or circuit failure, the self diagnostics drives the output to 3.6 or 21.0 mA, according to the user’s choice.

Foundation fieldbusTM: For sensor circuit failures, events are generated and status is sent to link outputs. Detailed diagnostics are available in the contained parameters. PROFIBUS PA: For sensor or circuit failures, status is sent to output parameters. Detailed diagnostics are available in the contained parameters. |

|

Temperature Limits

|

Ambient: -40 to 85 °C (-40 to 185 °F)

Process: -20 to 150 °C (-04 to 302 °F) Storage: -40 to 100 °C (-40 to 212 °F) Digital Display: -10 to 60 °C (14 to 140 °F) |

|

Turn-on Time

|

HART®: Performs within specifications in less than 5 seconds after power is applied to the transmitter.

Foundation fieldbusTM e PROFIBUS PA: Performs within specifications in less than 10 seconds after power is applied to the transmitter. |

|

Configuration

|

HART®: By digital communication (HART® protocol) using the configuration software CONF401, DDCON (for windows), HPC301 or HPC401 (for Palms). It can also be configured using DD and FDT/DTM tools.

Foundation fieldbusTM e PROFIBUS PA: Basic configuration may be done using the local adjustment magnetic tool if device is fitted with display. Complete configuration is possible using configuration tools. |

|

Static Pressure Limit

|

7 MPa (70 kgf/cm²) (1015 psi).

|

|

Humidity Limits

|

0 to 100% RH.

|

|

Damping Adjustment

|

0 to 32 seconds in addition to intrinsic sensor response time (0.2 s) via digital communication.

|

Performance Specifications:

|

Electrical Connection

|

1/2 - 14 NPT

M20 X 1.5 PG 13.5 DIN |

| Process Connection | Industrial Model: 316 SST Flange ANSI B16.5 4”. Sanitary Model: 304 SST Tri-clamp 4”. |

| Wetted Parts | Isolating Diaphragms: 316L SST or Hastelloy C276. Wetted O-Rings (For Sanitary Model): Buna N, Viton™ or Teflon™. |

| Nonwetted Parts | Electronic Housing: Injected aluminum with polyester painting or 316 SST. Complies with NEMA 4X, IP66/68 W. Fill Fluid: Silicone (DC200/20, DC704), Glycerin and Water, Neobee M20 Propylene Glycol. Cover O-Rings: Buna N. Identification Plate: Aço Inox 316. |

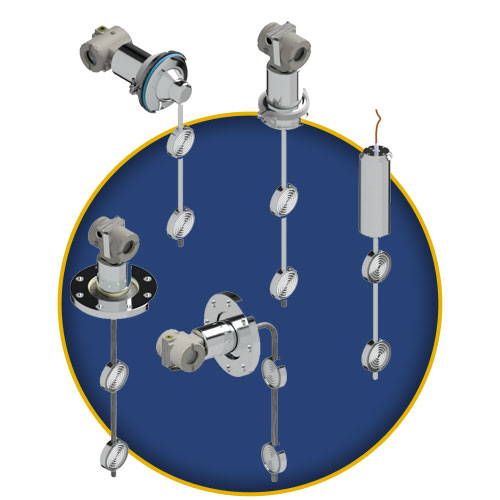

| Mounting | Side or top mounted. |

| Approximate Weights | 8 kg (18 lb) – Sanitary Model. 13 kg (26 lb) – Industrial Model. |

Physical Specifications

|

Reference Conditions

|

Temperature of 25 °C (77 °F), atmospheric pressure, power supply of 24 Vdc, silicone oil fill fluid, isolating diaphragms in 316L SST and digital trim equal to lower and upper range values.

|

| Accuracy | For range 1: ±0,0004 g/cm³ (±0,1 °Bx) For range 2: ±0,0007 g/cm³ Linearity, hysteresis and repeatability effects are included. |

| Stability (for 12 months) | For range 1: 0,021 x 10-³ g/cm³ For range 2: 0,083 x 10-³ g/cm³ |

| Ambient Temperature Effect (per 10 °C) | For range 1: 0,003 x 10-³ g/cm³ For range 2: 0,013 x 10-³ g/cm³ |

| Static Pressure Effect | Pressão Estática no ZeroZero Static Pressure For range 1: 0,001 x 10-³ g/cm³ For range 2: 0,004 x 10-³ g/cm³ |

| Power Supply Effect | ± 0.005% of calibrated span per volt.. |

| Mounting Position Effect | It can be eliminated after installation. No span effect. |

| Electro-Magnetic Interference Effect | Designed to comply with IEC 61326-1, IEC 61326-2-3, IEC 61000-6-4 e IEC 61000-6-2. |