DT300Series

Density Transmitters - Normalizing Tube

FLOW STANDARDIZATION SYSTEM IN DENSITY MEASUREMENTS

The Normalizing Tube refers to an innovative flow normalization system to minimize the interference of fluid turbulence in density measurements, when using density meters based on the differential pressure principle through measurements on two remote but fixed diaphragms.

Density measurement using the differential pressure principle consists of measuring the pressure difference between two diaphragms of identical dimensions and materials installed on a vertical axis and with a fixed distance between centers. In this measurement principle, it is important to ensure that only the differential pressure proportional to the distance and density is measured. In processes with excessive turbulence, the speed of the fluid through the diaphragms causes oscillation in the density measurement. In addition, suspended solids can cause damage to the diaphragms. Therefore, it is essential that these external interferences are minimized, for the sake of measurement accuracy and protection of the diaphragms.

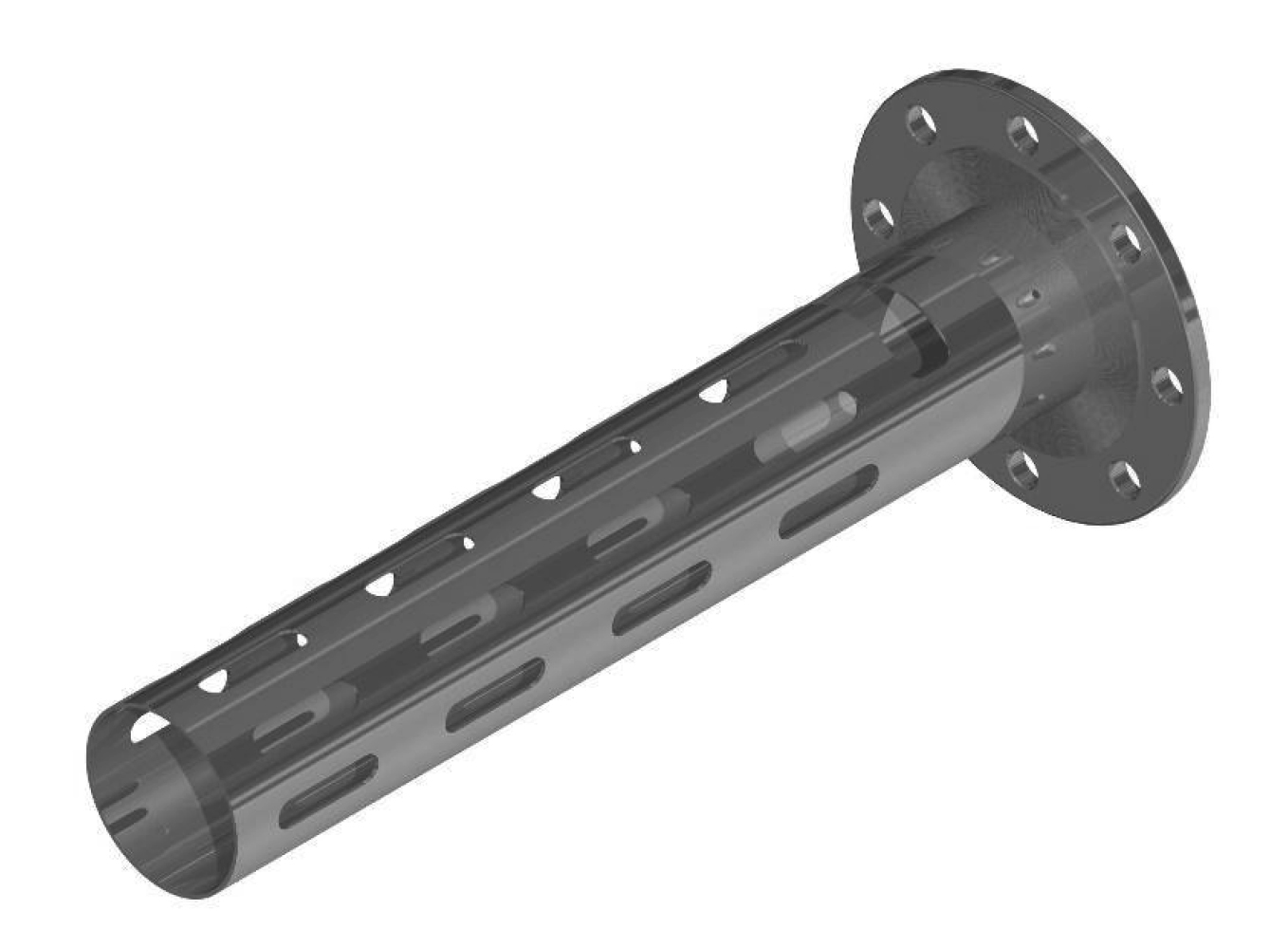

Therefore, we are presenting an innovative equipment with holes on only one side; the side with holes must be mounted facing the back of both diaphragms. These holes will direct the fluid into the normalizing bulkhead, ensuring constant recirculation of the fluid to be measured, without reaching the densitometer's measuring diaphragms at speeds that could increase measurement instability.

It is important to note that the Normalizing Tube was developed to be used as a casing for the densitometer rod where the two measuring diaphragms are mounted.

This Normalizing Tube was designed for use in processes with liquid fluids, with or without suspended solids, and with temperatures limited only by the density meter.

The invention can be better understood through the description above in conjunction with the corresponding figures below:

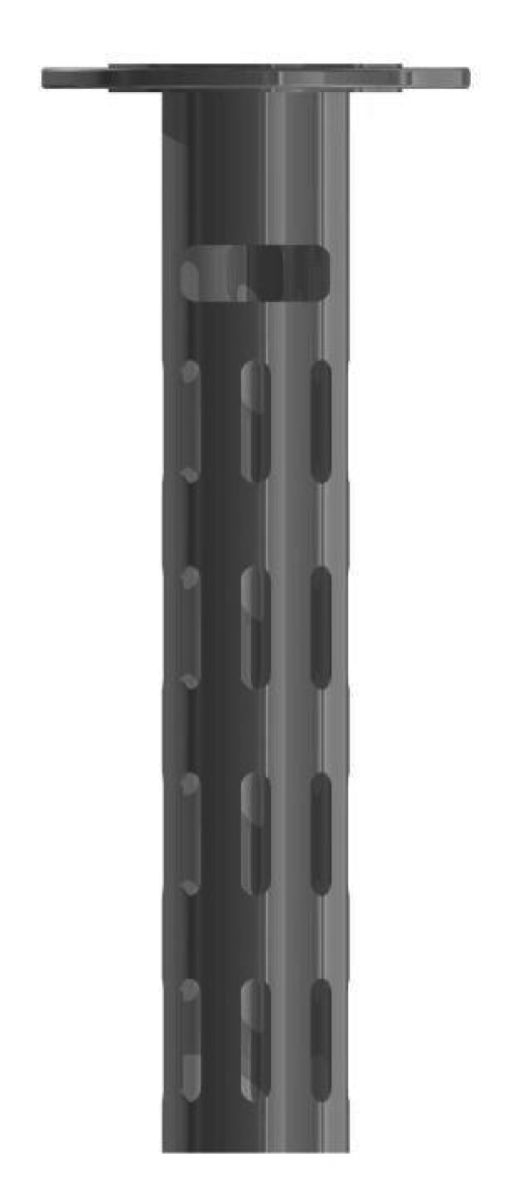

FIGURE 1 represents a front view of the Normalizing Tube and the fixing flange

FIGURE 2 is a perspective view of the Normalizing Tube.

FIGURE 3 represents a view of the Normalizing Tube assembly with the Densimeter.

The Normalizing Tube combines the function of reducing process turbulence, protecting the densitometer diaphragms and homogenizing the mixture, allowing the fluid density to be read, thus establishing the necessary controls for the applications.

The installation is done by positioning the densitometer on top of the Normalizing Tube, with the diaphragms facing the blind side (without holes) of the tube until the instrument (5) is fully supported on the flange (2), which is sealed by the appropriate joints and fasteners mentioned in the project.

The tube works as soon as the process passes through the densitometer, allowing the fluid to pass through the diaphragms without turbulence, obtaining the appropriate readings.